Blog · 6 MIN READ

Workflows at Work: Audio Visual Olfactory (AVO) Inspections

Posted on July 25

Audio, Visual, and Olfactory (AVO) inspections (including Method-22) are crucial for safety and reliability in oilfield and refinery operations. EPA’s Quad O regulations (OOOOa, OOOOb, and OOOOc) govern these inspections. They prevent fugitive emissions and costly compliance fines, which can start at $10,000 for simple oversights like open tank hatches.

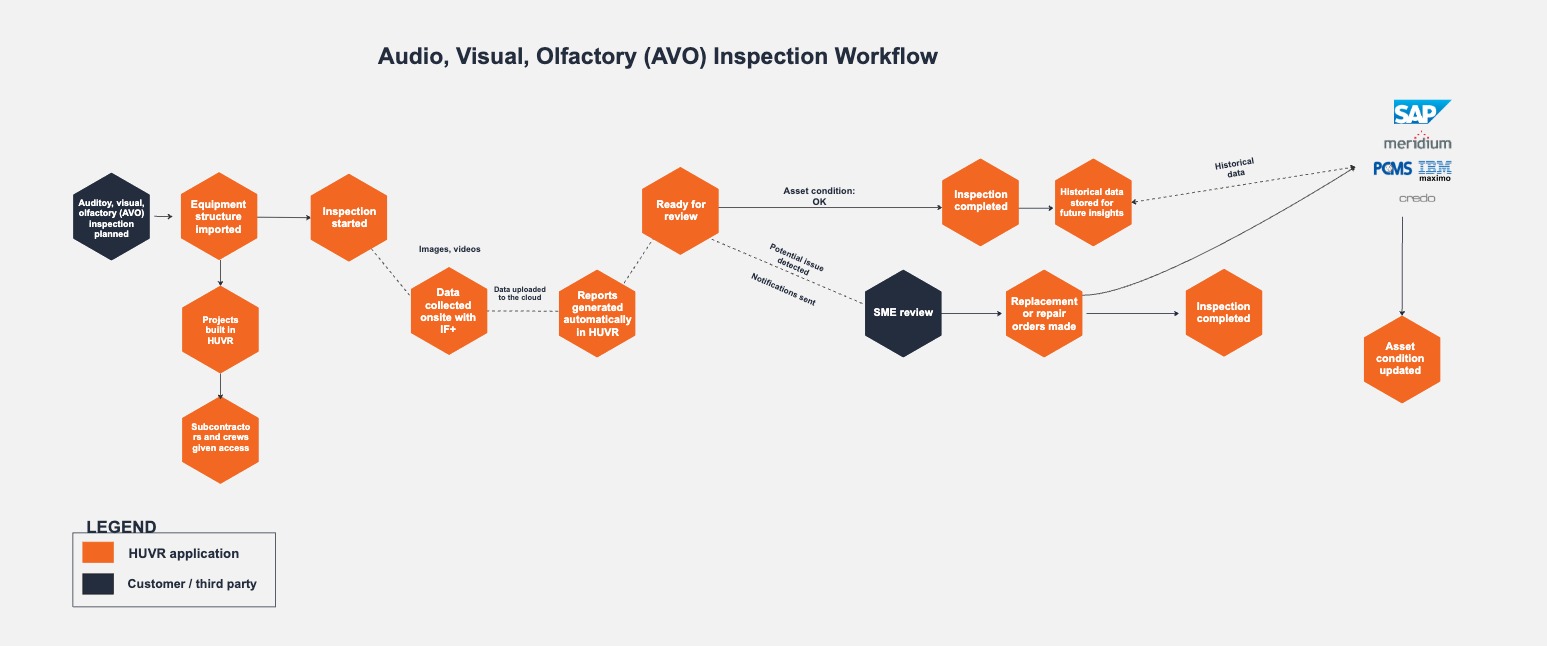

HUVR’s Reliability Automation Platform enhances AVO inspections by digitizing and standardizing the process. Our platform provides configurable technician checklists with geospatial data, start/stop times, and real-time reporting. This significantly boosts efficiency and ensures effortless compliance. With HUVR, organizations save time and money while easily meeting regulatory requirements.

What used to take a full day – finding data, scheduling, inspecting, and filling out a report – now takes just an hour.

— Production Foreman

SET-UP

Effective organization is paramount for high-volume inspections. HUVR’s dedicated support team collaborates with asset owner/operators. Together, they establish a project structure tailored to their asset hierarchy. This brings clarity and organization to all technicians and team members within a centralized interface.

Standardized and Configurable Checklists: AVO inspection checklists include pre-set choices, asset-owner-defined language, and geolocation-enabled start/stop time tracking. This configurability allows organizations to effectively monitor and enforce compliance. It ensures critical items, such as closed tank hatches or lit flares, are taken care of. Standardization guarantees consistent and reliable data from the field every time, providing invaluable insights for long-term asset monitoring.

Automated Scheduling and Access: We assign configurable projects and checklists to crews. Our support team helps build an automatic notification schedule, which drastically reduces planning time. Technicians receive automatic notifications when AVO inspections are due. We grant team members access on an as-needed basis, ensuring efficient inspection completion while safeguarding sensitive data.

Real-time Dashboards: At this stage, we configure dashboards and standard reporting structures. Both management and technicians can monitor these in real-time for a holistic view of operational efficiency.

EXECUTION

Upon notification from HUVR’s Reliability Automation Platform, technicians proceed to tank farms for AVO inspections. GPS location capture precisely contextualizes inspection data. It records exact locations of entry, exit, and findings. This ensures accuracy in tracking leaks or damage and enhances efficiency.

Digital Field App: Technicians use HUVR’s InspectFlow+ field app on any iOS or Android device. They replace cumbersome paper checklists with streamlined digital ones. They can capture photos and videos to objectively document asset erosion and leaks. Users can even configure checklist items to require photo evidence for elements like tank latches and flare stacks. This guarantees regulatory compliance and significantly reduces errors and fines. Standardized checklists ensure data from the field reports consistently and objectively, minimizing reliance on subjective observations.

Simplified Project Management: HUVR simplifies inspection tracking. It allows inspectors to manage multiple projects within a single, intuitive interface. This eliminates the need for multiple paper documents and manual coordination. Technicians can complete all inspections effortlessly from one centralized view.

Instant Cloud Upload and Integration: Back at the office, field data is instantly uploaded to the secure HUVR cloud. We store it indefinitely and seamlessly integrate it with existing systems. Technicians and experts gain a clear, long-term perspective on asset integrity.

Automated Reporting: HUVR automatically generates detailed reports with field data saving time. For extended capabilities, HUVR also integrates with various business intelligence and inspection data management tools via open API.

REMEDIATION

HUVR’s reporting and dashboard tools provide critical insights. They empower organizations to take prompt action on any identified issues, and we record the data specifically for compliance purposes. If no issues are detected, asset condition information is uploaded to the cloud to inform future inspections.

When an issue is identified, we promptly notify relevant Subject Matter Experts (SMEs). They can easily review findings and swiftly order necessary actions, including replacement seals and O-rings or repair workflows for loose fittings. Technicians can do repairs on the spot and document them directly within the inspection. We thoroughly document the entire resolution process, creating a clear historical chain for future inspectors and asset owners. This enhances long-term asset health, compliance, and reliability.

OUTCOME

HUVR enables more efficient and easily trackable AVO inspections.

- Say goodbye to paper checklists: Our digital solution simplifies organization both in the field and office.

- Rich photo and video documentation: This eliminates guesswork and provides superior data compared to traditional methods.

- Standardized, configurable digital checklists: They effortlessly catch commonly missed items, helping organizations avoid regulatory fines up to $10,000.

- Precise location data and start/stop times: These contextualize inspection findings, ensuring compliance and offering valuable long-term insights for continuous improvement.

The HUVR platform seamlessly integrates with virtually any system of record. It empowers organizations to track and manage assets, leading to improved long-term reliability and maintenance decisions. Ultimately, conducting AVO inspections with HUVR translates to significant time and cost savings through enhanced efficiency and regulatory compliance.

Curious to learn how HUVR can transform your operations? Explore more cost-reducing workflows in our ‘Workflows at Work’ series, or schedule a conversation with a HUVR expert today to see how we can replicate this success for your business.