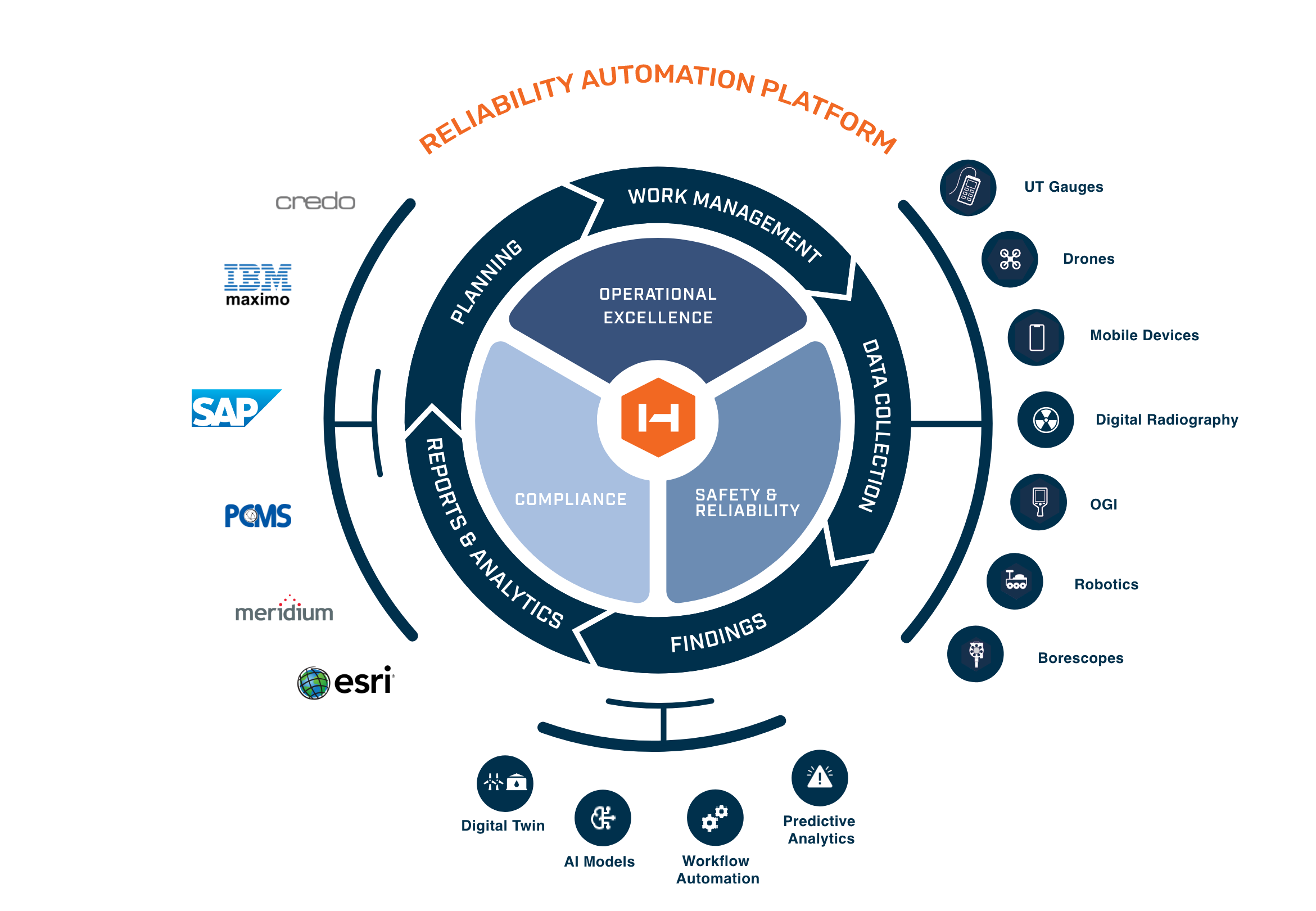

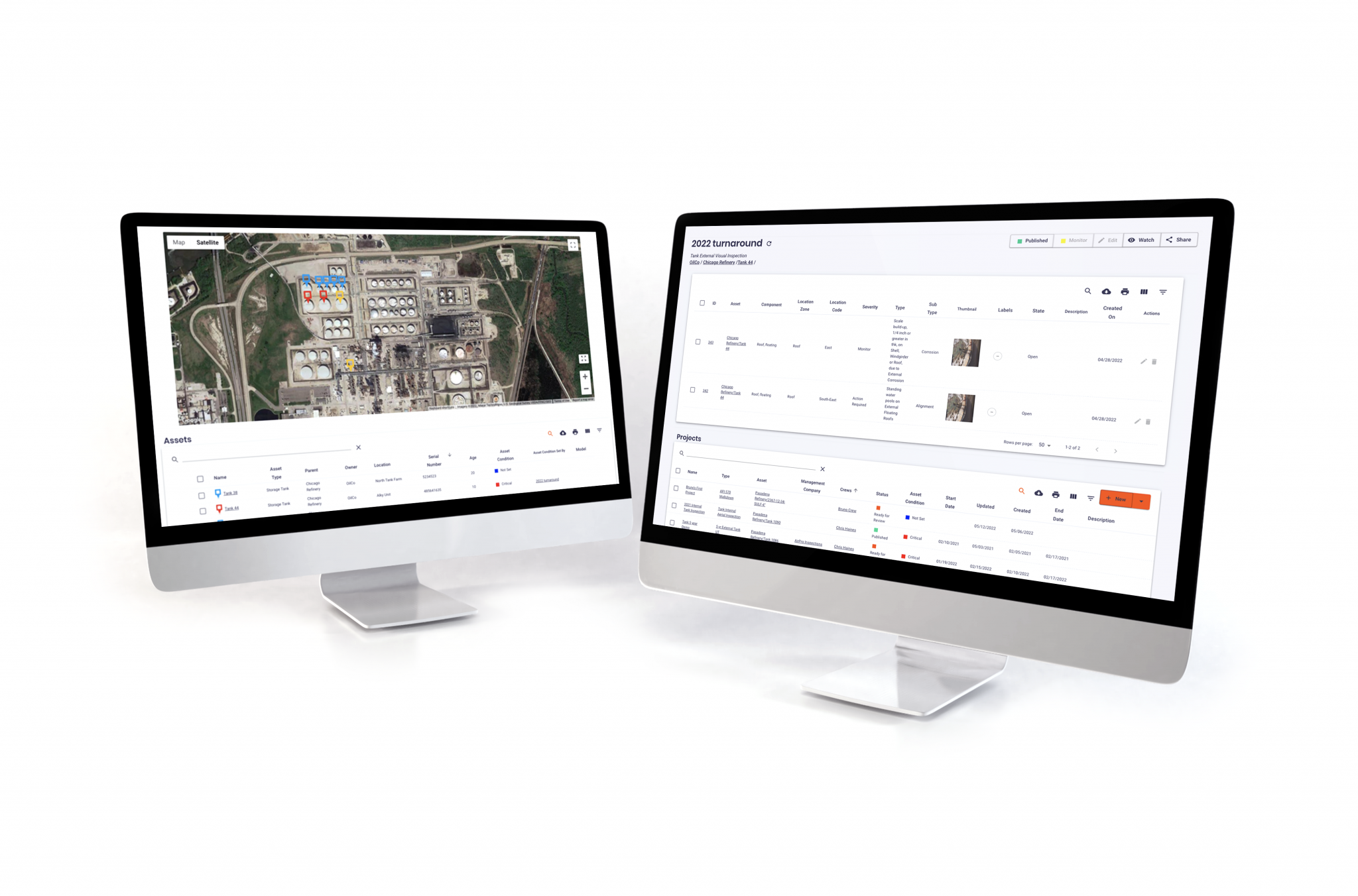

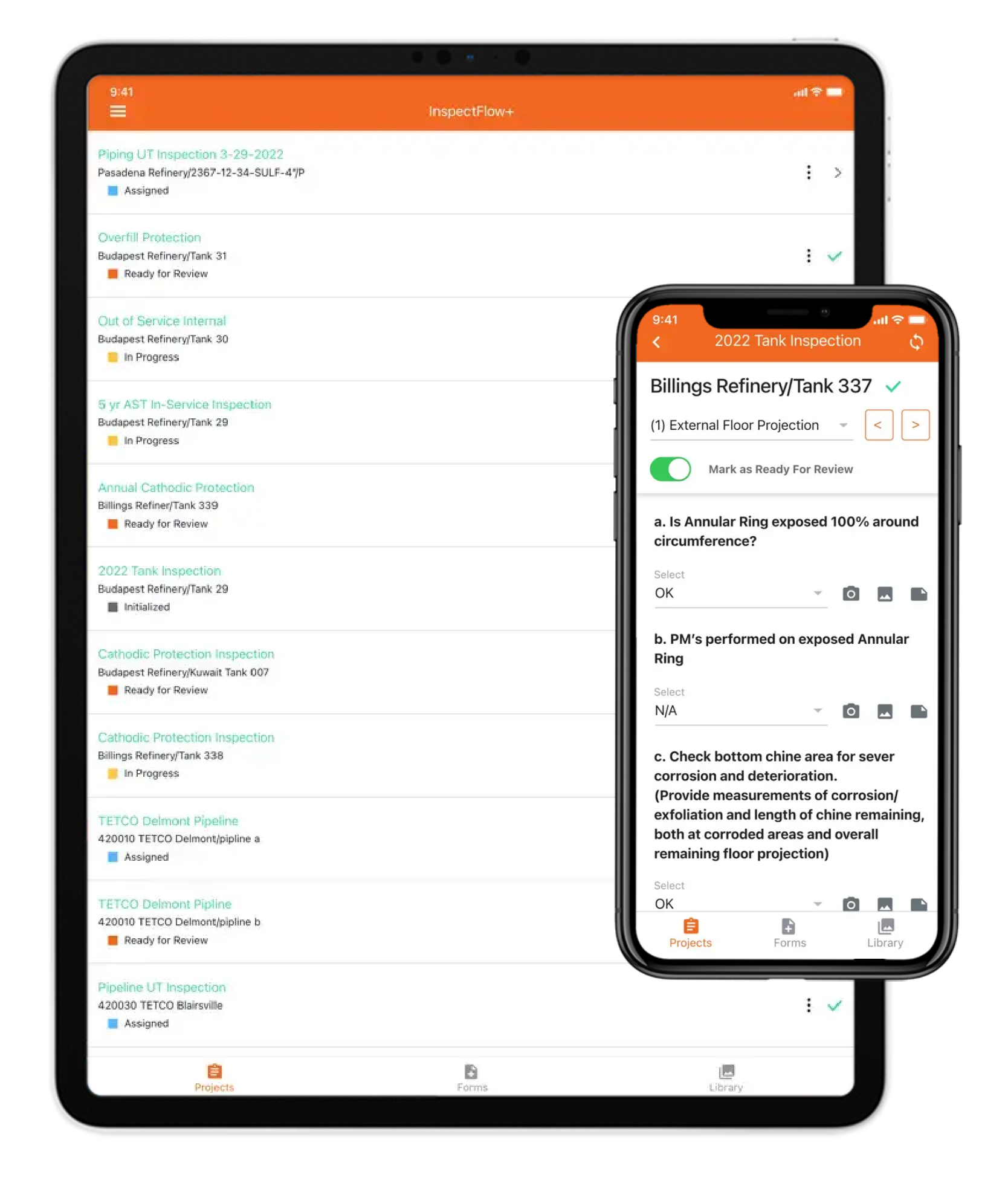

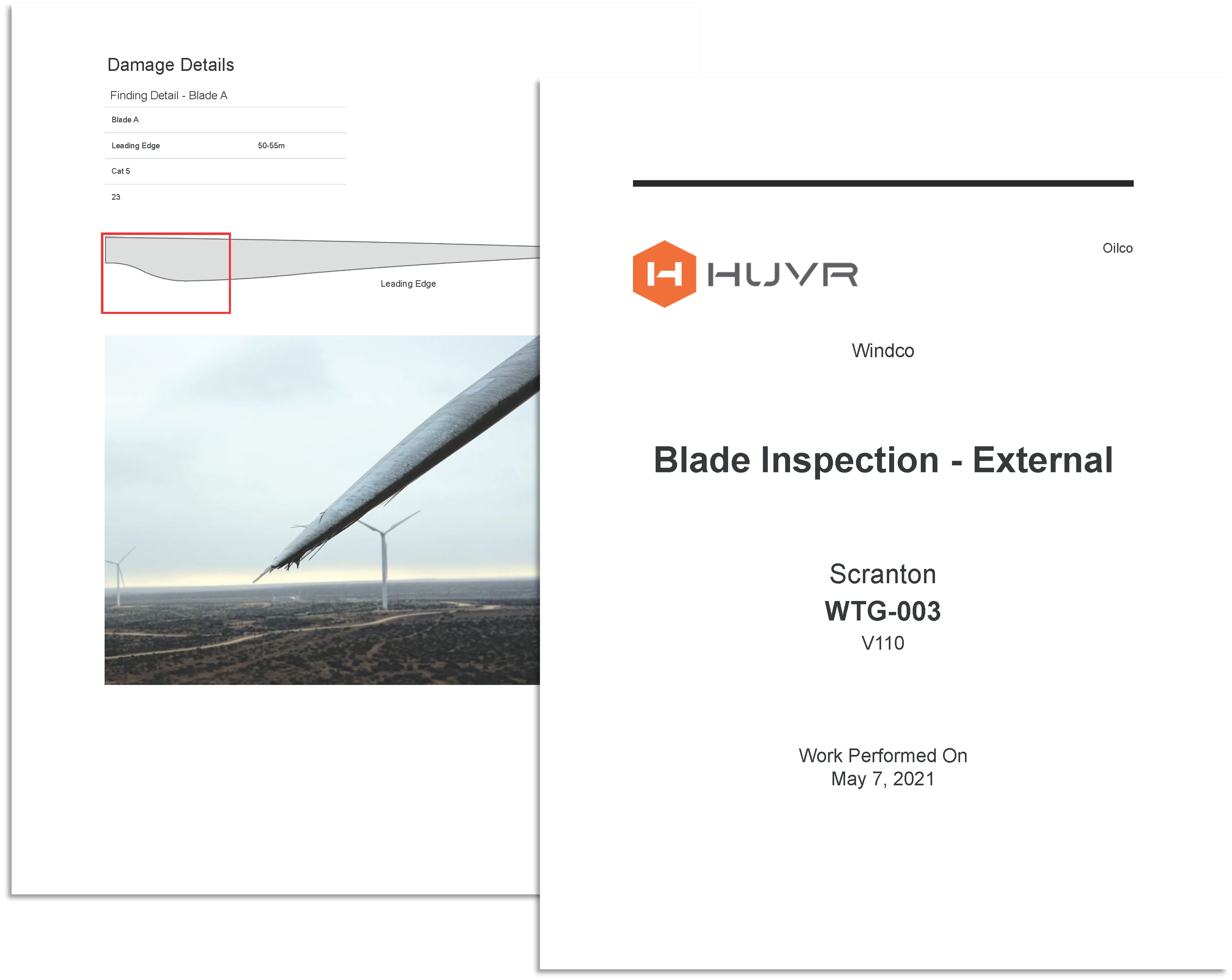

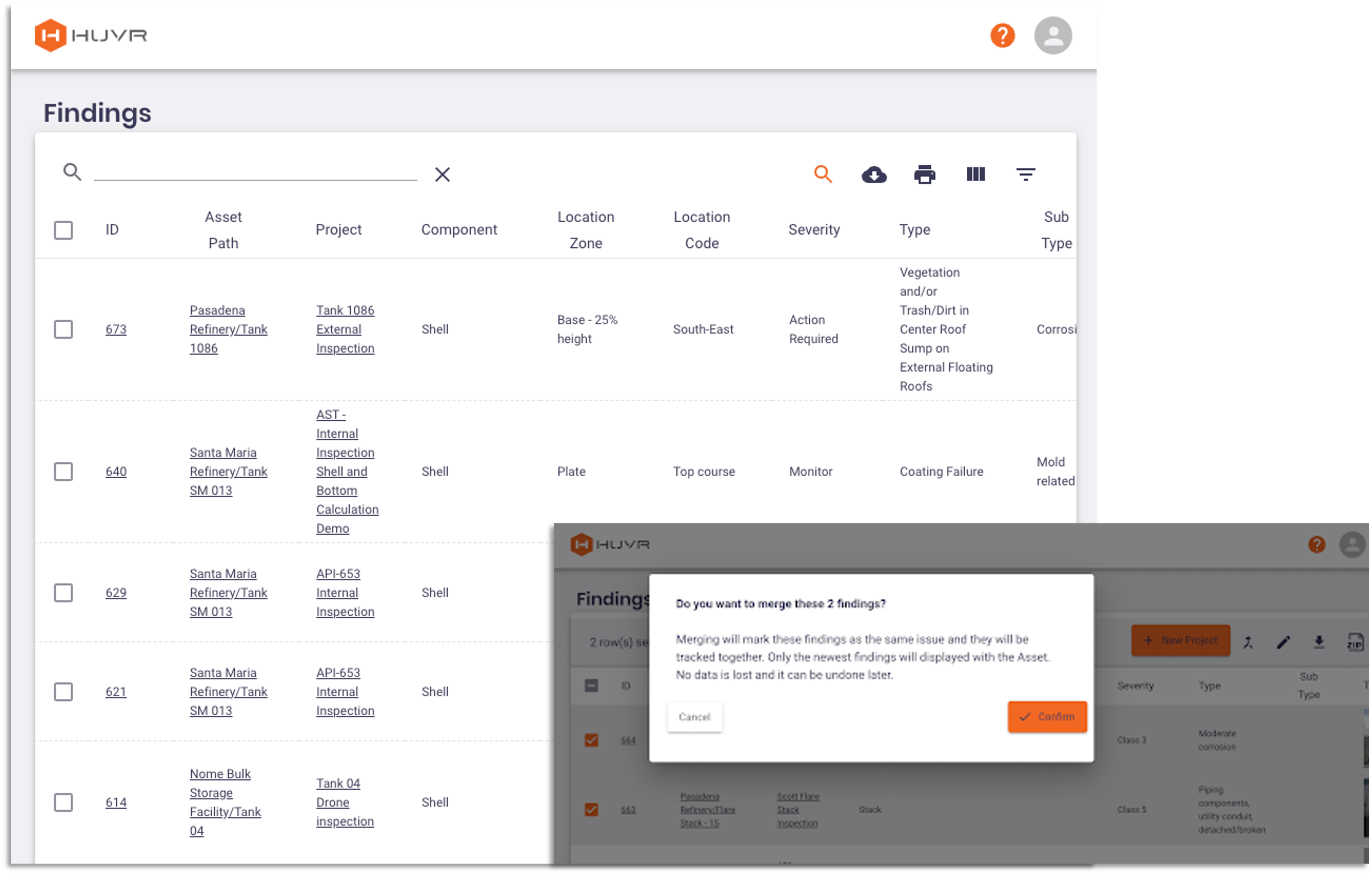

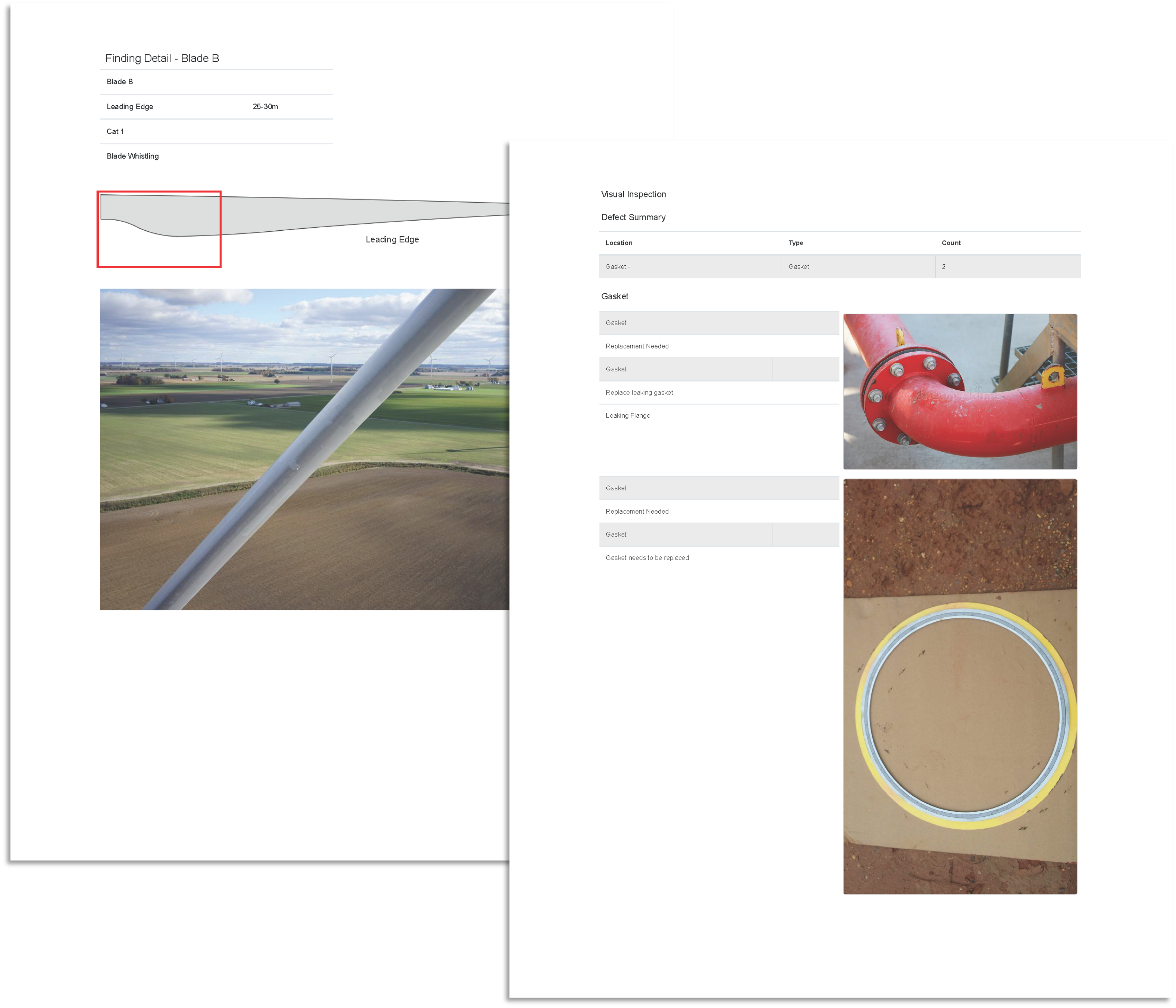

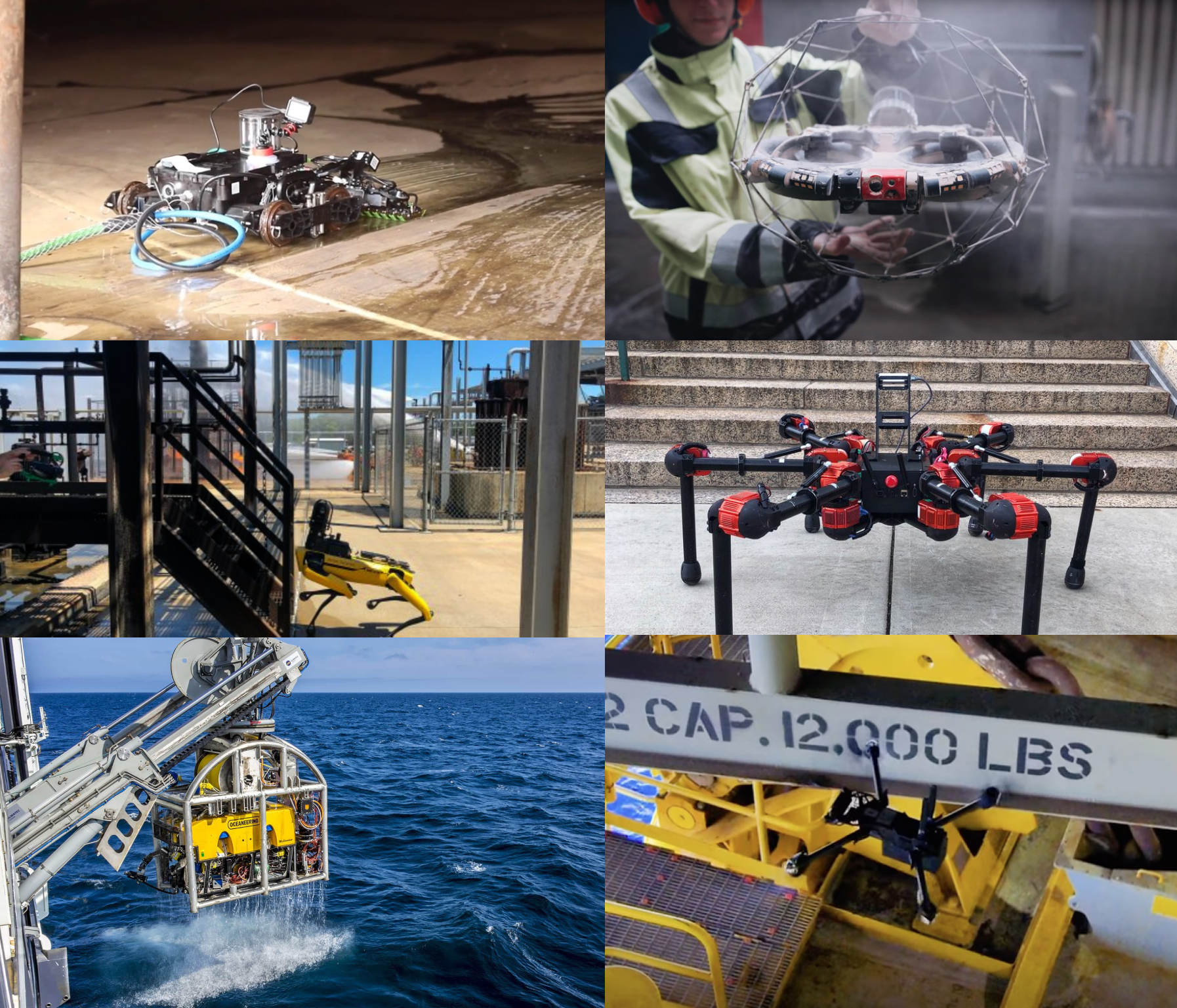

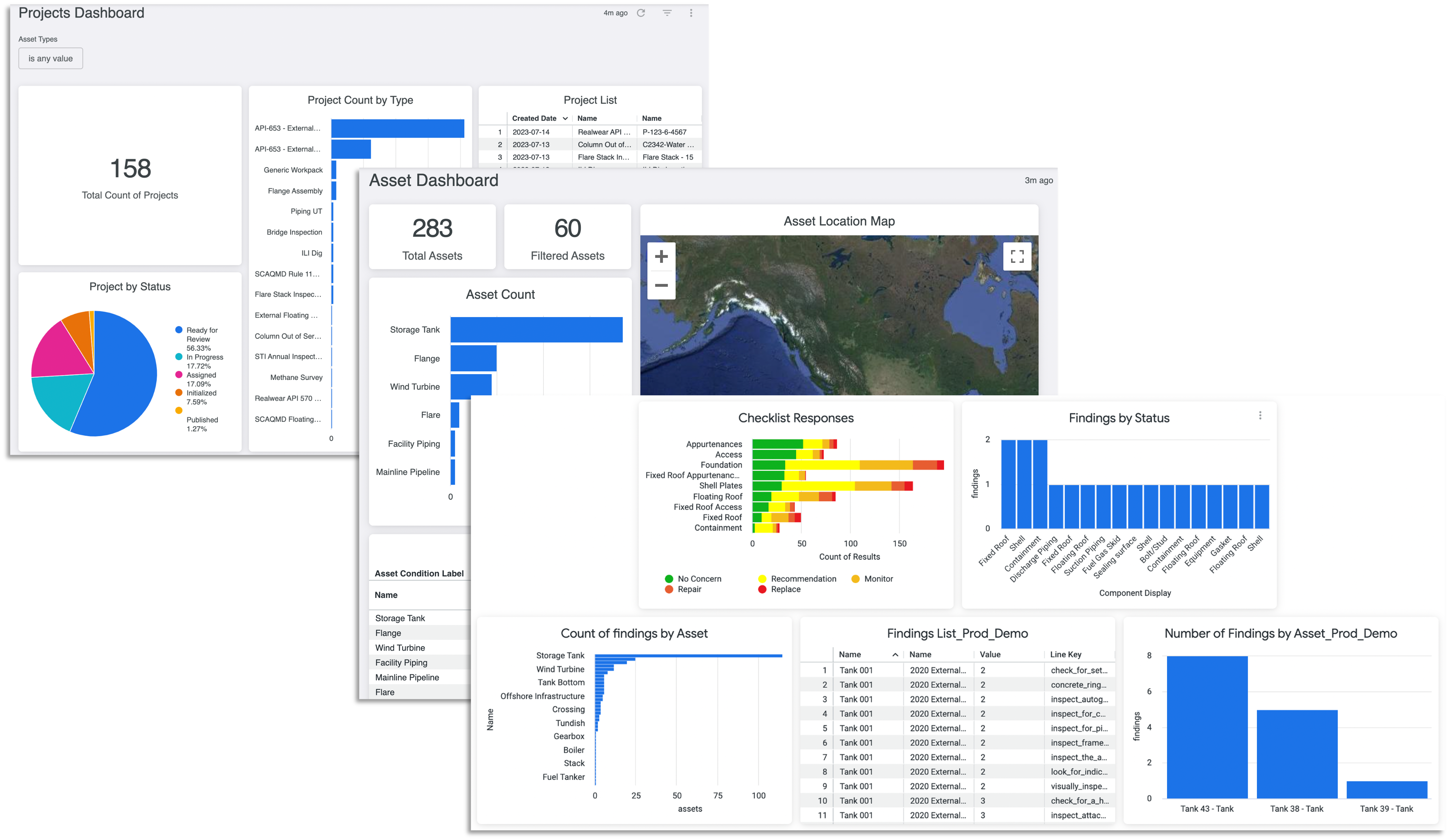

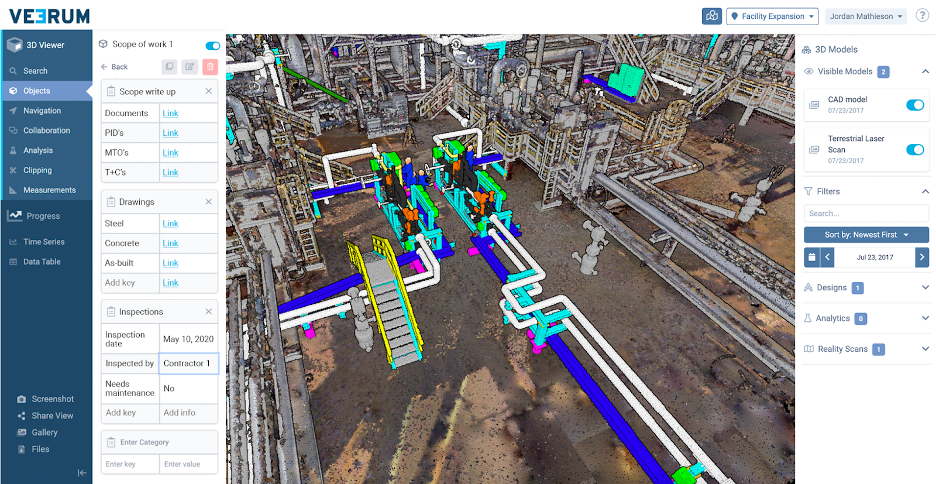

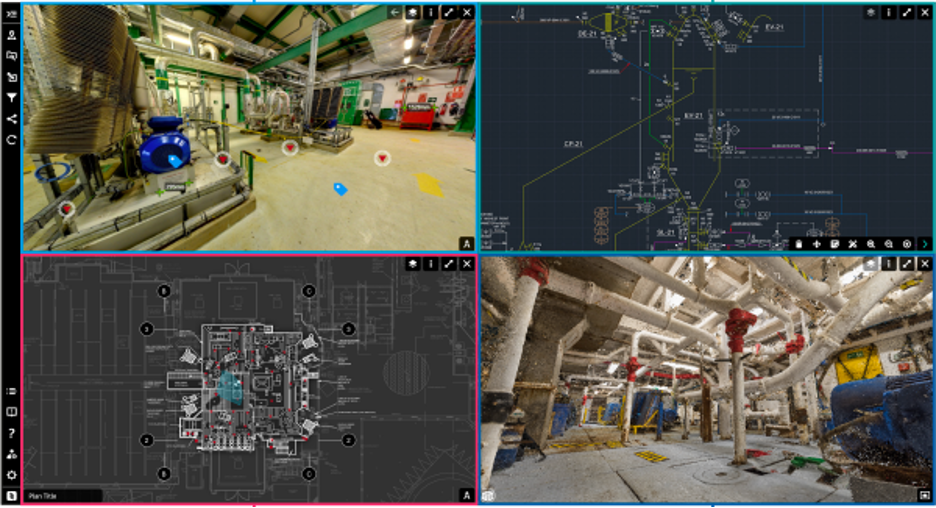

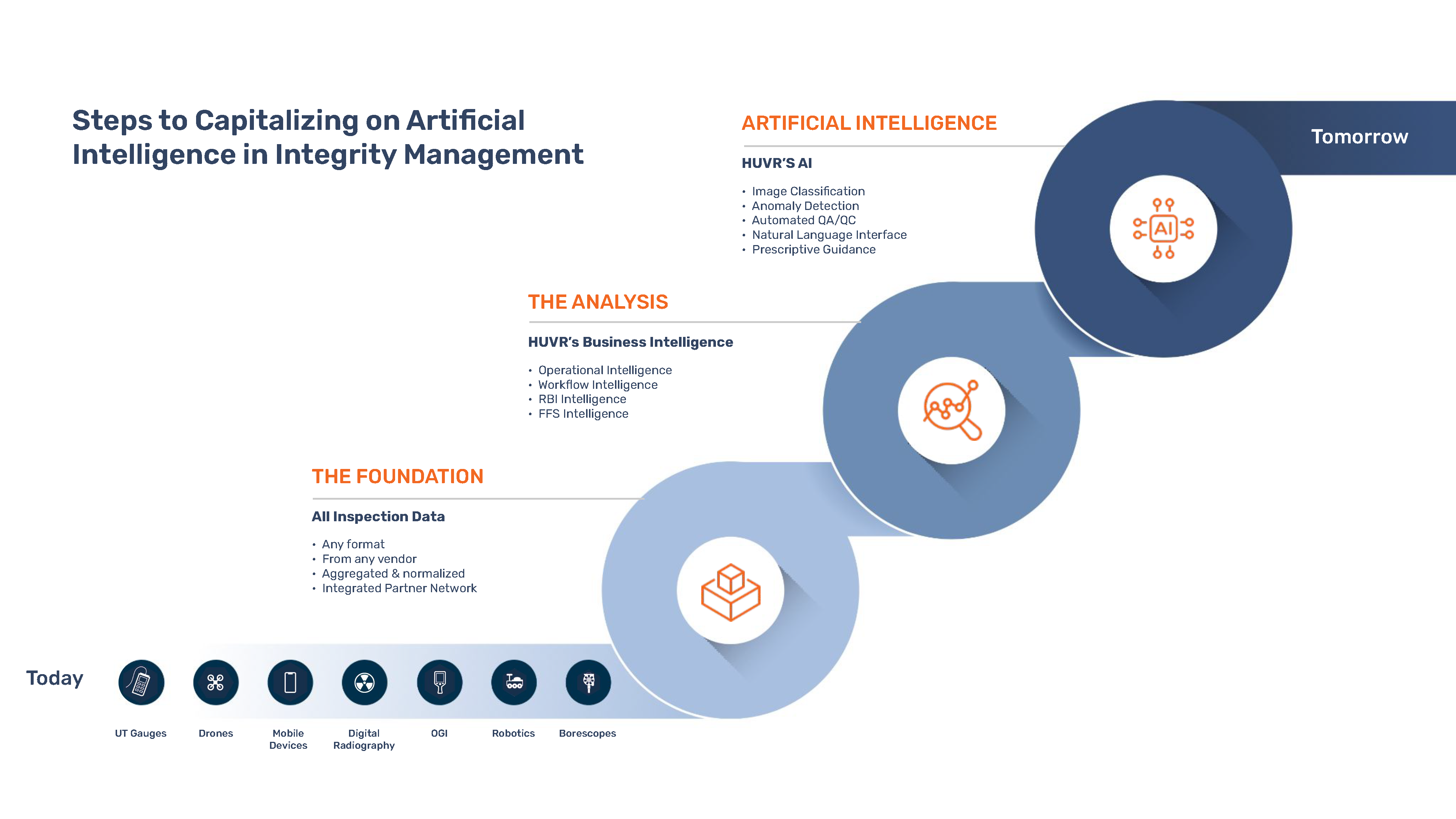

HUVR is a cloud-based Reliability Automation Platform purpose-built for managing inspection and asset data. It provides an enterprise-grade, centralized software hub with web and mobile applications for collecting, normalizing, storing, automating and analyzing all inspection data types. Best practices workflow processes are documented and automated, and libraries of relevant media are maintained. Visual asset hierarchies, map views and strong document management features drive immediate operational benefit. Secure, partitionable access empowers you AND your contractors ensuring consistency and efficiency. The ever expanding HUVR Partner Network integrates the HUVR Reliability Automation Platform with more than 40 leading inspection software and hardware providers for simple – often autonomous – data ingestion and deep analysis, and the open architecture allows easy connectivity with other IDMS Systems of Record. Powerful data intelligence, including project, asset and crew analytics and customizable workflow dashboards deliver data-driven insights that can be easily actioned with built-in anomaly management functionality.

Streamline, store and organize, automate, analyze, and share your inspection data using HUVR today, so that you’re ready to capitalize on AI, autonomy and a more visual way of managing asset integrity tomorrow.