In a world saturated with digital forms and checklist tools, the HUVR Checklist Engine stands apart. We understand that a checklist isn’t just about ticking boxes; it’s about capturing, connecting, and leveraging critical data to drive better decisions. Our engine is purpose-built for the complexities of industrial asset management, transforming your workflows into intelligent, data-driven processes.

Beyond Basic Checklists: Why HUVR is Different

Many tools offer digital forms, but HUVR’s Checklist Engine is engineered with a singular focus: your data, your assets, your inspection history.

Deeply Connected Data

Unlike standalone checklist apps, HUVR’s engine is intrinsically linked to your existing asset and inspection history. This connection empowers predictive maintenance, streamlines compliance, and eliminates data silos.

Digitize Any Workflow with Ease

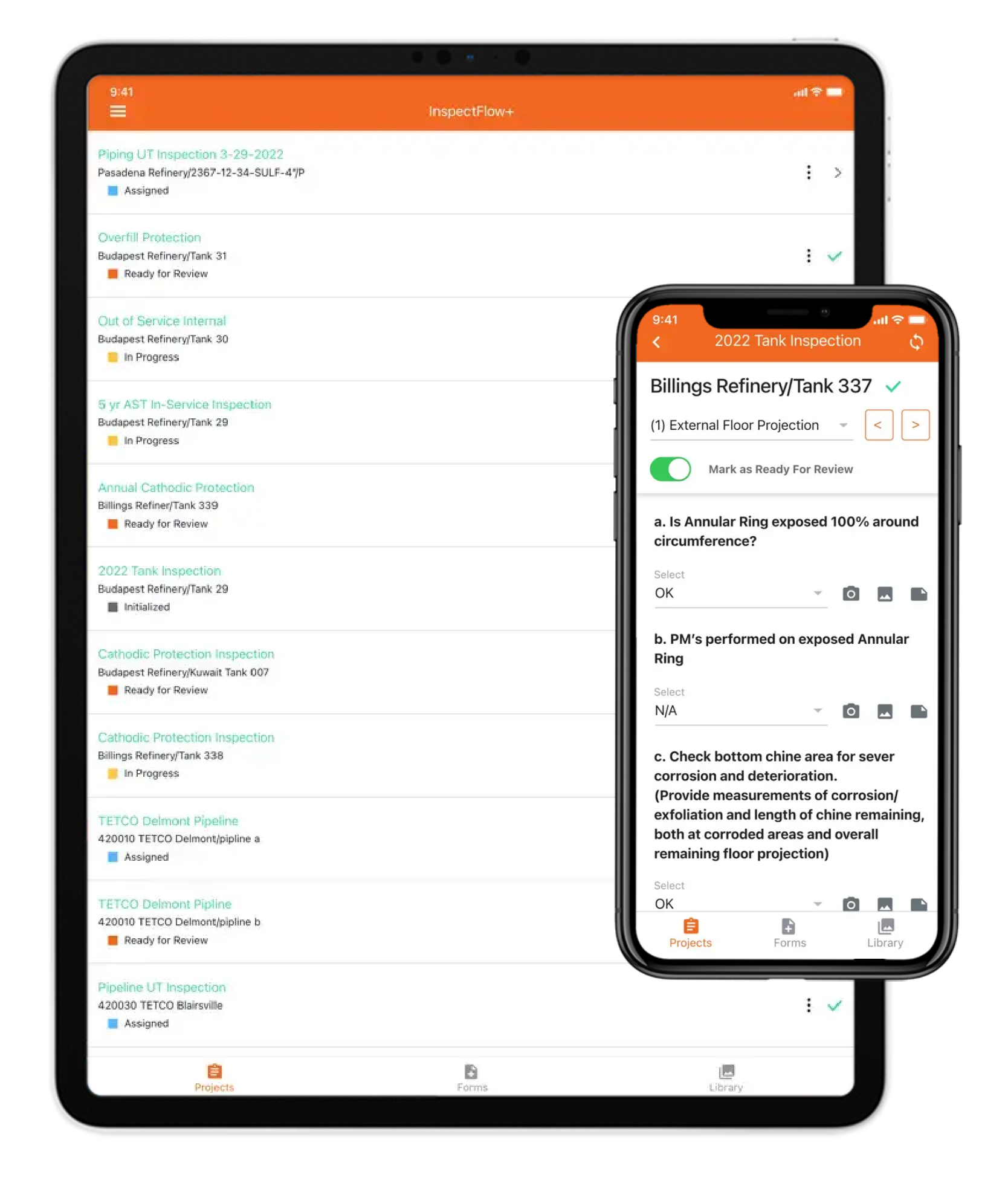

Our intuitive checklist template engine allows you to seamlessly digitize even the most complex operational workflows. From routine inspections to intricate maintenance procedures, transform paper-based processes into dynamic digital forms. Need to make large-scale updates? Bulk edit capability via Excel makes it easy to manage and update templates.

Powerful, Excel-Like Calculation Engine

Say goodbye to manual calculations and error-prone data entry. The HUVR Checklist Engine features a robust, Excel-like calculation engine built directly into your forms. Define complex formulas, automate data derivations, and ensure data integrity right at the point of collection, giving your field teams immediate insights and reducing post-inspection processing time. For example, customers use this calculation engine to automatically score inspections based on weighted answers, providing an immediate health assessment of an asset or location.

Intelligent Field Data Integration

Our applications aren’t just about collecting data; they’re about making data work for you in the field.

- Geo-Location Tagging: Automatically tag inspection data with precise geographical coordinates, validate location of your field workers.

- Pull Data into the Field: Empower your technicians with instant access to relevant asset history, previous inspection results, and critical operational data directly on their device.

- Push Data Back to Your Database: Seamlessly integrate field-collected data back into your central database, ensuring a single source of truth and enabling real-time reporting and analysis. For example, if an inspector identifies a discrepancy in an equipment’s serial number during a field inspection, they can update it directly within the checklist, and that change will reflect in your central asset database.

Smart Validation & Contextual Guidance

The HUVR Checklist Engine goes beyond simple data capture, offering intelligent validation to guide your teams and prevent errors.

Rich Media Integration & Annotation

Connect relevant media – photos, videos, and documents – directly to your checklist items. More than just attachment, our engine allows you to annotate media with detailed markups, arrows, and text, providing crystal-clear communication and actionable insights directly from the field.

Enhanced NDT Inspection Capabilities

For Non-Destructive Testing (NDT) inspections, the HUVR Checklist Engine provides specialized functionality to ensure accuracy and continuity:

- Previous Measurement Context: Technicians can view previous measures for specific NDT locations directly on their mobile device. This immediate historical context is crucial for identifying trends and anomalies.

- Smart Validation on Historical Data: Our engine offers smart validation based on those previous values, alerting the inspector if a new reading falls outside acceptable parameters or indicates a significant change, preventing critical errors.

- Detailed Location Information: Access comprehensive details about the Condition Monitoring (CML) or Thickness Monitoring (TML) location directly on the mobile device, including schematics, historical data points, and specific testing parameters, ensuring precise and consistent data collection.

Seamless Integration with Findings Management

The true power of the HUVR Checklist Engine is realized through its seamless integration with the HUVR Findings Management module. As your teams complete checklists, any identified issues, anomalies, or deviations can be automatically or manually escalated into actionable findings. This direct link ensures:

- Instant Issue Capture: Findings are created directly from checklist responses, eliminating manual data transfer and reducing the risk of oversight.

- Streamlined Remediation Workflows: Each finding is assigned, tracked, and managed through its lifecycle, from identification to resolution, ensuring accountability and timely corrective actions.

- Comprehensive Audit Trails: Maintain a complete history of all findings associated with an asset, providing valuable data for root cause analysis and continuous improvement initiatives.

- Data-Driven Prioritization: Leverage the rich data collected via checklists to prioritize findings based on severity, impact, and asset criticality.

Experience the HUVR Difference

Stop managing checklists and start managing data. The HUVR Checklist Engine empowers your field operations with intelligent workflows, and real-time dashboards.