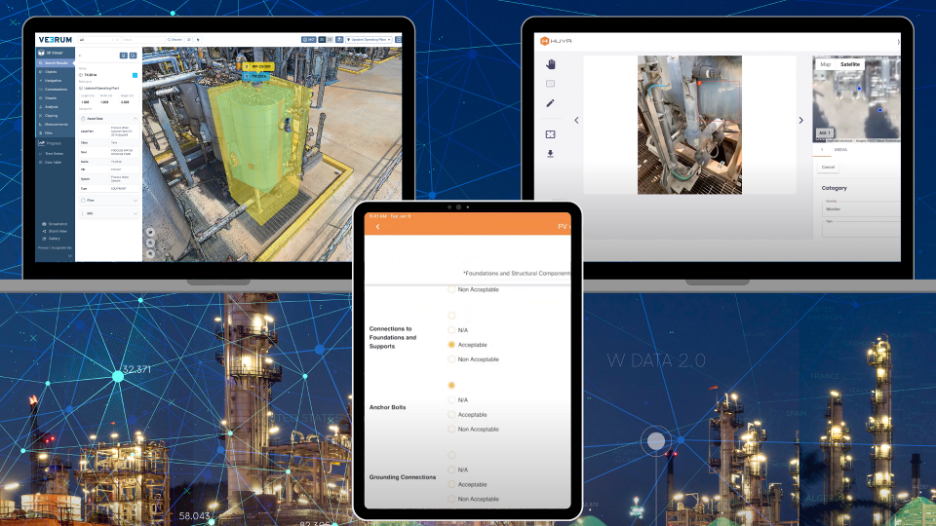

Combining HUVR’s simple-to-use inspection data platform with VEERUM’s 3D digital twin technology offers unparalleled context to industrial asset owners and inspectors.

PARTNERSHIP

HUVR and VEERUM

An inspection solution for hard-to-get-to remote industrial assets

Existing remote industrial assets are difficult to access. Asset teams need to frequently travel to site to conduct inspections and plan maintenance projects. These trips are inefficient, costly, and risky. Enter HUVR and VEERUM, enabling a new visual way to conduct inspections.

With HUVR’s simple-to-use inspection data platform visualized in VEERUM’s lightweight digital twin application, asset owners around the world are transforming how they conduct remote inspections. The purpose built solution transforms the way workflow data is collected, managed, and delivered to asset owners.

VEERUM and HUVR in action

Build the virtual site: Using your new or existing reality data including pointclouds and 360 panoramic photos, your remote site is built and visualized in VEERUM.

Data collection: Your existing systems of record and IoT devices are integrated and geolocated to HUVR and VEERUM through open API data sources.

Inspection: Using VEERUM, users can perform site walkthroughs of the remote site and create and update inspection records linked directly to the HUVR application.

Status visualization: With VEERUM and HUVR, asset stakeholders can update inspection and maintenance status to keep geographically distributed teams on the same page. Colored status symbols give a quick and easy to understand indication of asset health and identifies where work needs to be done.

Benefits of Working Digitally

- Customizable: Match your existing organizational best practices and workflows with custom inspection data

- Cloud hosted: All the latest asset data is stored and visualized on the cloud for secure access from anywhere in the world. Users are confident they are working with the latest information to make data-informed decisions.

- Automated reports: Inspection reports are automatically generated as inspection data is added to the HUVR system

- Reduce travel to site: Remote inspections reduce the need for expensive, time-consuming, and risky travel to site.

- Aggregated information: Collect and deliver all available asset information to quickly identify data gaps and jobs to be done.