Industrial inspection is undergoing a transformation. This shift is driven by the increasing adoption of robotic systems and unmanned aerial vehicles (UAVs), commonly known as drones. These technologies are not just enhancing efficiency; they are fundamentally improving safety, reducing costs, and providing unprecedented data insights across critical sectors.

Robots in Industrial Inspection: A Growing Force

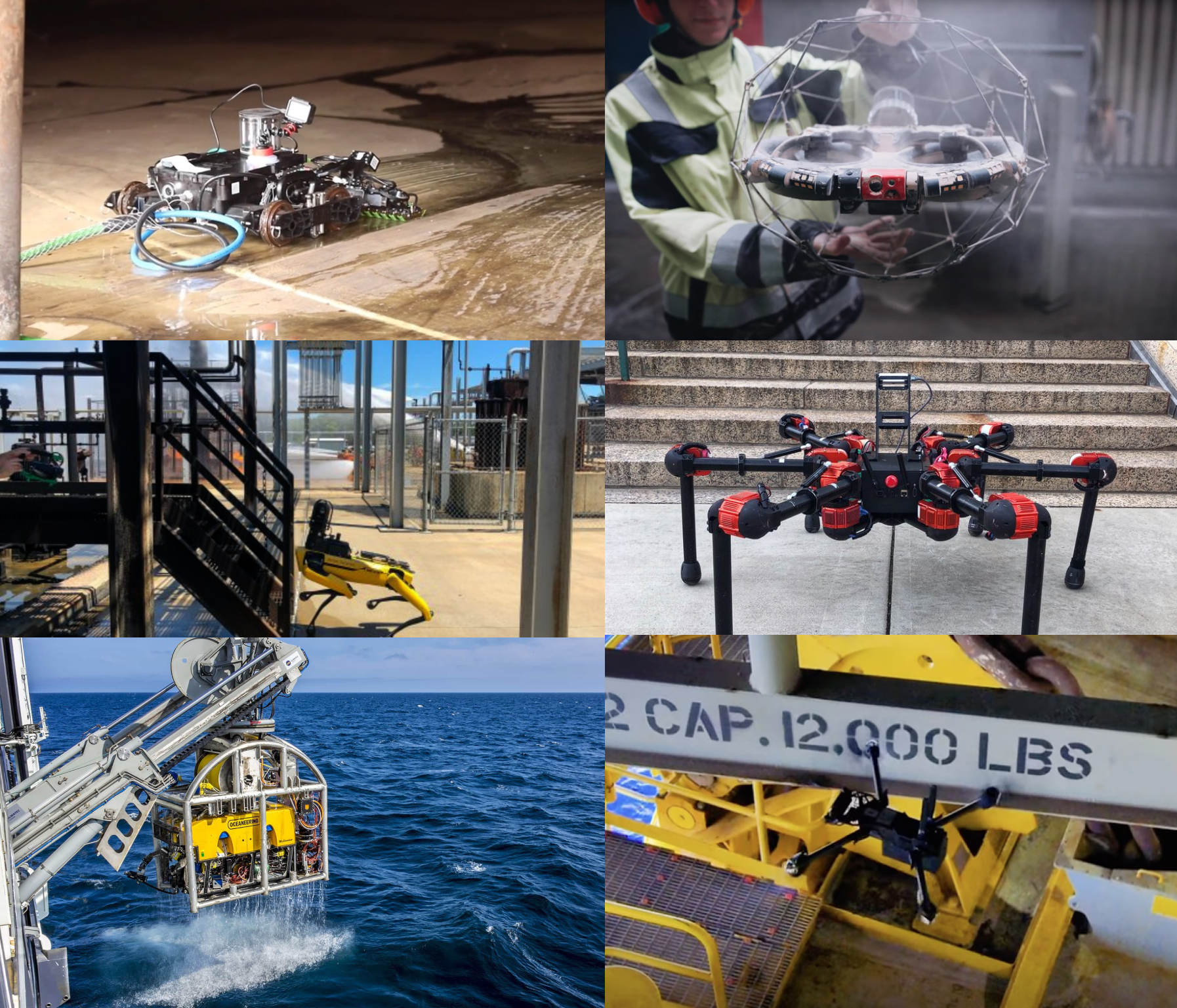

Beyond the factory floor, specialized inspection robots are becoming indispensable tools. They assess complex and hazardous environments. These intelligent machines are designed to navigate challenging terrains, confined spaces, and dangerous conditions. They collect vital data that human inspectors often cannot.

Key Statistics and Trends:

- Market Expansion: The global Inspection Robots Market is experiencing rapid growth. It was valued at approximately USD 2.85 billion in 2023. It is projected to reach nearly USD 10 billion by 2032. This shows a robust Compound Annual Growth Rate (CAGR) of 16.9% from 2025 to 2032.

- Driving Factors:

- Enhanced Safety: A primary driver is the need to minimize human exposure to high-risk areas. This applies to industries like petrochemicals, power generation, and oil & gas. Robots perform tasks in environments too dangerous for humans.

- Technological Sophistication: Advances in Artificial Intelligence (AI), machine learning, and sensor technologies are making inspection robots smarter and more capable. They can now identify microscopic faults. They process complex data in real-time. They adapt to changing conditions with minimal human intervention.

- Predictive Maintenance: The shift towards predictive maintenance strategies relies heavily on the continuous, accurate data collected by these robots. This enables industries to anticipate and prevent equipment failures.

- Diverse Applications: Inspection robots are deployed across various critical applications, including:

- Oil & Gas: Inspecting pipelines, storage tanks, and critical components in refineries.

- Energy & Utilities: Assessing the integrity of power lines, wind turbines, and solar infrastructure.

- Infrastructure: Monitoring bridges, tunnels, and other public utilities for structural integrity.

- Manufacturing: Performing quality control checks and visual inspections on production lines.

Drones: Soaring to New Heights in Inspection

Drones have emerged as a game-changer for aerial and visual inspections. They offer unmatched flexibility, speed, and safety for assessing vast or elevated assets.

Key Statistics and Trends:

- Explosive Market Growth: The Industrial Drone Inspection Market is set for significant expansion. It is projected to reach USD 4,621 million by 2035. This is a substantial increase from USD 746 million in 2024. It will grow with an impressive CAGR of 18.0% from 2025 to 2035.

- Broader Impact: The wider Drone Based Inspection Services Market is forecast to reach USD 39.1 billion by 2031. It will grow at a CAGR of 15% from 2025-2031. This highlights the widespread adoption of drone-enabled inspection services.

- Core Advantages:

- Unparalleled Safety: Drones eliminate the need for human inspectors to climb dangerous structures or enter hazardous zones. This drastically reduces the risk of accidents and injuries.

- Efficiency and Cost Savings: They can cover large areas rapidly. They collect high-resolution data in minutes. They reduce the need for expensive equipment like scaffolding or manned aircraft. This leads to significant time and cost efficiencies.

- Superior Data Quality: Equipped with high-resolution cameras, thermal imaging, and LiDAR, drones capture detailed visual and quantitative data. This enables more thorough and accurate assessments.

- Widespread Applications: Drones are transforming inspection across numerous industries:

- Construction & Infrastructure: Monitoring construction progress. Performing structural inspections of bridges and buildings.

- Energy & Utilities: Inspecting power grids, wind farms, solar arrays, and oil and gas infrastructure.

- Telecommunications: Assessing the condition of cell towers and communication infrastructure.

- Maritime: Inspecting ship hulls, offshore platforms, and subsea assets.

HUVR: The Data Backbone for Modern Inspections

Robots and drones excel at collecting vast amounts of inspection data. However, effectively managing, analyzing, and deriving actionable insights from this data presents a significant challenge. This is where platforms like HUVR play a critical role. They act as the central data backbone for the entire inspection ecosystem.

HUVR’s Reliability Automation Platform is purpose-built in the cloud. It aggregates, analyzes, and automates visual and quantitative inspection data from any device, sensor, robot, or field technician. It addresses the common industry problem of data silos. This is where valuable information from diverse inspection tools remains fragmented and underutilized.

How HUVR Enables Robotic Inspections:

- Vendor-Agnostic Data Ingestion: HUVR ingests data from a multitude of sources. This includes advanced robotic systems (like quadruped robots and subsea ROVs), drones, traditional Non-Destructive Testing (NDT) tools, and even manual checklists. This ensures all inspection data, regardless of its origin or format, resides in a single, secure repository.

- Data Normalization and Standardization: The platform standardizes disparate data formats. This makes it consistent and usable for comprehensive analysis. This eliminates laborious manual processes of copying, pasting, and integrating data, which often lead to inefficiencies and missed insights.

- Advanced Analytics and Reporting: HUVR provides powerful dashboards and automated reporting capabilities. Users can visualize asset health at a glance. They can drill down from fleet-level overviews to individual asset defects. They can generate customized reports for QA/QC, regulatory compliance, and strategic decision-making.

- Workflow Automation: HUVR streamlines the entire inspection workflow. This includes planning inspections, managing crews, ingesting data, and assessing findings. This automation significantly reduces administrative overhead. It also accelerates the time from data collection to actionable insights.

- Enhanced Collaboration: By centralizing data and providing secure, partitionable access, HUVR enables collaboration. This is between internal teams, external contractors, and stakeholders. It ensures everyone is working with the latest, most accurate information.

- Driving ROI: By improving data management, enabling predictive maintenance, and enhancing operational efficiency, HUVR helps industrial asset owners realize significant returns on their investments in robotic and drone inspection technologies. This leads to improved reliability, reduced downtime, and substantial cost savings.

In conclusion, the combination of advanced robotic and drone inspection capabilities with robust data management platforms like HUVR is defining the next generation of industrial asset integrity management. This integration empowers industries to operate more safely, efficiently, and proactively in an increasingly complex world.