HUVR’s Diagram-Driven Inspection (DDI) tool provides a visual guide to contextualize inspections for planners, technicians, and leadership alike. Paper drawings and maps have traditionally been an important part of inspection planning and execution. The “X” marking the spot is valuable context to asset engineers and maintenance teams. With DDI, HUVR keeps this valuable context and gets rid of the hassle of paper.

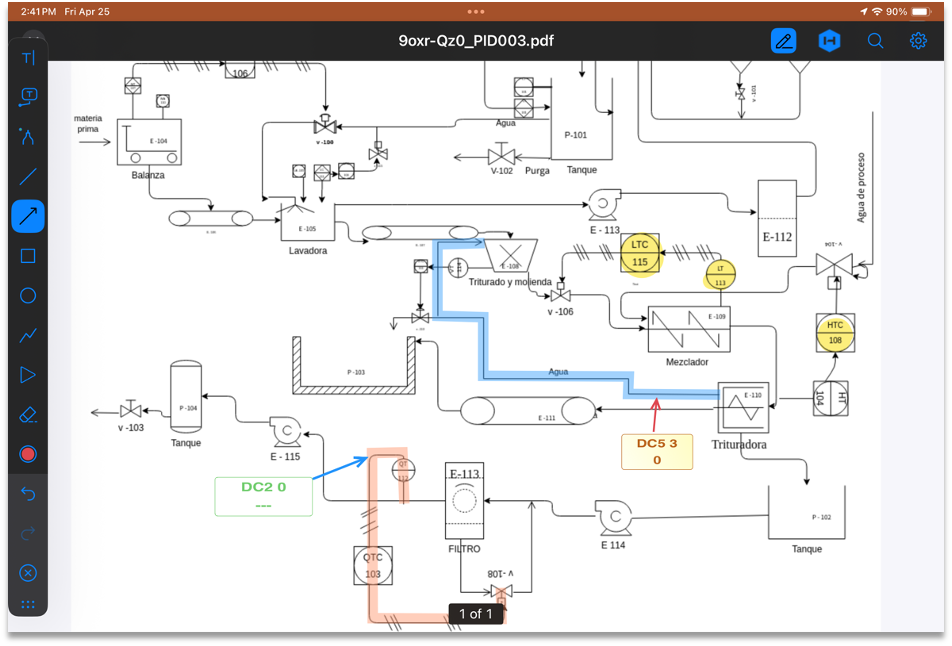

With DDI, teams can upload and use any PDF—be it a drawing, diagram, or isometric—as the basis for their inspections. Plan inspections, manage findings in the field, and review critical information, all guided by a visual ‘treasure map’ that provides the invaluable ‘X marks the spot’ context.

Why DDI? The Value Proposition

Traditional paper-based processes rapidly create cumbersome inefficiencies for administrative tasks and field-based work. Repetitive and time-intensive tasks like building reference binders full of documentation and diagrams or sifting through resources onsite to locate and report on asset anomalies can tack hours of additional time onto an inspection.

Diagram-Driven Inspections (DDI) is a tool in HUVR that drives visual guidance and context for planners, technicians, and leadership involved in key inspection and maintenance processes. Users of this feature report streamlined processes, faster field execution, and unified collaboration and communication across their teams.

One oil and gas organization’s site leadership recognized a need to modernize their paper-based processes for their visual and ultrasonic testing (UT) inspections. Operating from HUVR’s diagram-driven inspection (DDI) tool, this organization’s planning, inspection, and leadership teams were able to transform their process to remove paper, reduce the planning time required by 50%, and reduce the inspectors’ “paperwork” time to almost 0.

From planning to field execution, all your teams are on the same page with DDI.

Streamlined Planning & Preparation

- Digitized Reference Materials: Eliminate hours spent manually creating and maintaining inspection documents. Upload, annotate, and access reference materials centrally, effectively eliminating the need for physical binders.

- Dynamic Historical Data: Historical insights are no longer hidden in spreadsheets or paper files; they are dynamically linked to assets for simplified planning.

- Reduced Administrative Burden: Slash inspection planning and prep time by digitizing annotation of diagrams and inspection plans.

Faster, Safer, and More Efficient Field Execution

- Visual Guidance in the Field: Technicians can immediately access annotated digital representations of the planned work and past inspection data.

- Reduced Cognitive & Physical Load: Minimize the burden on technicians by replacing bulky binders and notebooks with a tablet.

- Contextualized Findings: Annotate digital diagrams in the field to provide quick, contextualized insights for any findings.

- No more manual data entry or magic excel spreadsheets to maintain.

Unified Collaboration & Stronger Insights

- 95% Reduction in Post-Inspection Reporting & Transcription: Automated reporting and in-the-field data collection free teams up to focus on more critical tasks. Eliminate post-field transcription, resulting in fewer errors and faster action.

- Clear Anomaly Visualization & Standardization: With HUVR, you define the language around findings, including severity levels and the types of problems to be found. Even set the color on the PDF based on the details in Findings. All this makes your results more standard across inspectors, teams, and subcontractors, ensuring teams can act quickly on findings instead of spending days deciphering reports.

- Proactive Maintenance Planning: The contextualized data supports smarter maintenance planning and execution.

- Maintenance Execution: Easy hand-off to the maintenance teams directly in HUVR. Or connect to your existing system and link to the details from HUVR.

- System Integrations: Integrate with your existing enterprise IDMS technology (e.g., GE APM, PCMS) for easier adoption and ensuring all your data is not siloed, with the flexibility to link back to HUVR for additional details.

Visualize with Us

Curious if this could be right for your team? Discuss your workflows with a member of the team; reach out to see if our DDI solution could be right for you.